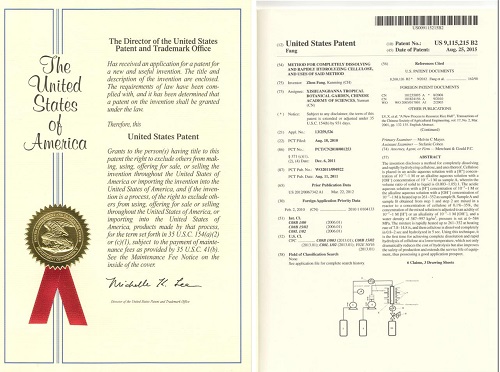

Recently, “fast dissolution of cellulose for hydrolysis” invented by Prof. Zhen Fang was authorized US patent (US patent#: 9115215; issue date: 08/25/2015).

In the nature, lignocellulosic biomass, such as wood and grass, is roughly consisted of 50% cellulose, 25% hemicellulose, and 20% lignin. Cellulose can be hydrolyzed into saccharides which are further used for producing cellulosic ethanol through fermentation. Because lignocellulosic biomass is water-insoluble, the current industrial methods for hydrolyzing biomass proceed mainly in a semi-continuous percolating reactor containing 0.4~0.8% dilute aqueous sulphuric acid, at temperature of 180~190℃ and under pressure of 12~14 atmospheres. Reports about continuous production of sugars in a high-pressure continuous flow reactor were not found.

Prof. Fang invented a method for completely dissolving and rapidly hydrolyzing cellulose, and uses thereof.

(i) Cellulose is placed in an acidic aqueous solution with a [H+] concentration of 10-7~1 M or an alkaline aqueous solution with a [OH-] concentration of 10-7~1 M as sample A, wherein the volume ratio of solid to liquid is (0.003~1.05).

(ii) The acidic aqueous solution with a [H+] concentration of 10-7~1M or the alkaline aqueous solution with a [OH-] concentration of 10-7~1M is heated up to 261~352℃ as sample B.

(iii) Sampe A and sample B obtained from step 1 and step 2 are mixed in a reactor to a concentration of cellulose of 0.1%~35%, the concentration of the mixed solution is adjusted to an acidity of 10-7~1M [H+] or an alkalinity of 10-7~1M [OH-], and a water density of 587~997 kg/m3, pressure is set at 6~584 MPa. The mixture is rapidly heated up to 261~352℃ at heating rate of 7.8~14.8℃/s, and then cellulose is dissolved completely in 0.8~2 sec and hydrolyzed in 5 sec. Using this technique, it is the first time for achieving complete dissolution and rapid hydrolysis of cellulose at a lower temperature, which not only dramatically reduces the cost of hydrolysis but also improves the safety of production and extends the service life of equipment in a flow system, thus possessing a good application prospect.

|