Biodiesel is a fuel obtained from renewable biomass feedstock that can be used in diesel engines as neat fuel or blended at various proportions wih conventional fossil-diesel fuel. At present, the high cost of biodiesel is the major obstacle for commercialization.

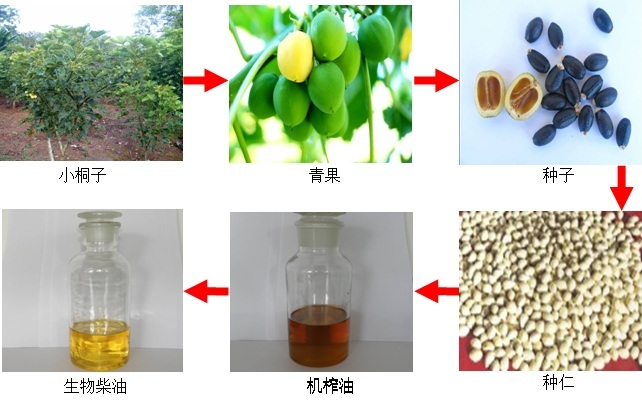

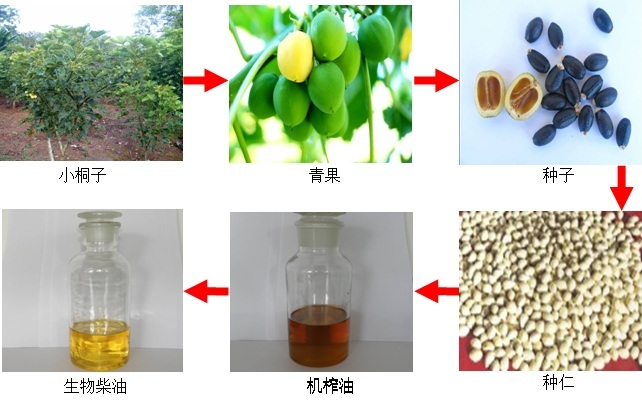

Jatropha curcas oil is a potential cheap feedstock for biodiesel production as compared with refined and edible-grade oils such as rapeseed oil, soybean oil and sunflower oil that are common feedstock in USA and Europe.

Prof. Fang Zhen and his research team of XTBG studied the transesterification of high free fatty acid content oil with methanol to biodiesel catalyzed directly by NaOH and high-concentrated H2SO4 or by two-step process in an ultrasonic reactor at 60°C. Their research result was as the following:

If NaOH was used as catalyst, biodiesel yield was only 47.2% with saponification problem. With H2SO4 as catalyst, biodiesel was increased to 92.8%. However, longer reaction time (4h) was needed and the biodiesel was not stable. A two-step, acid-esterification and base-transesterification process was further used for biodiesel production. It was found that after the first-step pretreatment with H2SO4 for 1 h, the acid value of Jatropha oil was reduced from 10.45 to 1.2 mg KOH/g, and subsequently, NaOH was used for the second-step transesterification. Stable and clear yellowish biodiesel was obrained with 96.4% yield aftr reaction for 0.5 h. The total production time was only 1.5 h that is just half of the previous reported. The two-step process with ultrasonic radiation is effective and time-saving for biodiesel production from Jatropha oil.

The research concluded that the two-step process coupled with ultrasonic rdiation is an efficient method for biodiesel production from crude oil with high FFA (free fatty acid ) value, and might find a practicle application.

Related research observation entitled Ultrasonic transterification of Jatropha curcas L. oil to biodiesel by a two-step process has been published in Energy Conversion and Management (2010) 51: 2802-2807. DOI: 10. 1016/ j. enconman. 2010. 06.017.